The Elbow Jet is capable of making up to three separations at one time!

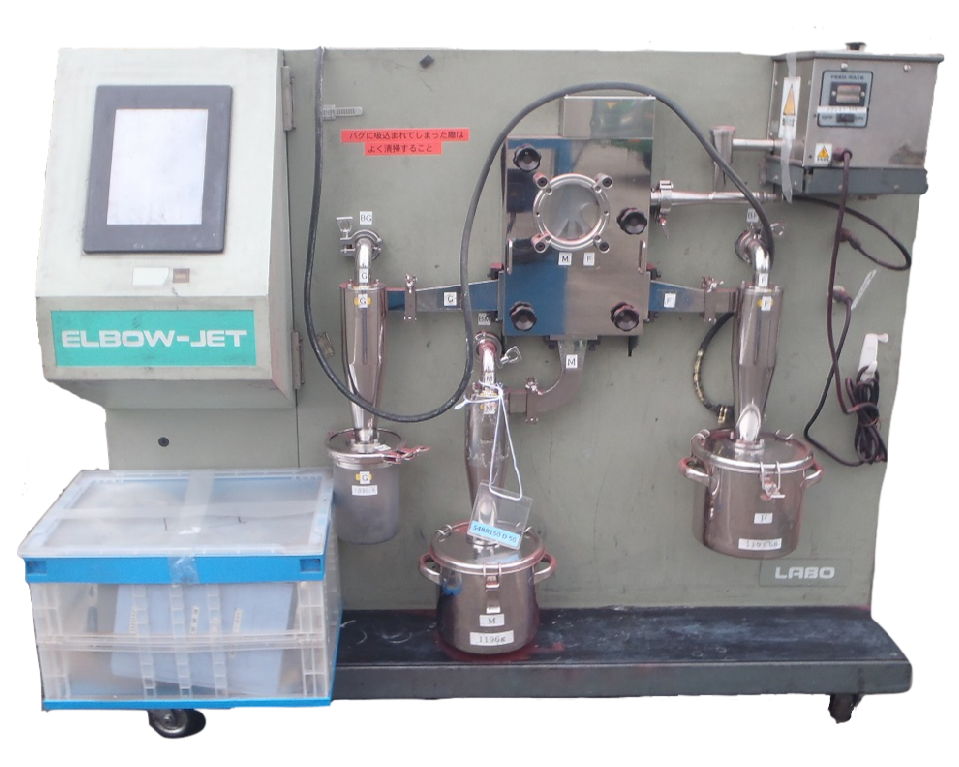

The Elbow Jet Air Classifier is the world’s first air classifier capable of performing simultaneous, multiple classifications of fine, dry powders. The Elbow Jet Air Classifier contains no rotating parts due to the fact it relies on airflow and does not contain a classifying wheel. The elimination of these parts makes the Elbow Jet ideal for abrasive and high purity powders and makes it the perfect fit for the BioMedical and Aerospace industries. The Elbow Jet is capable of making up to three separations at one time!

The Coanda Effect:

“If a surface is placed near a freely flowing Jetstream, that Jetstream will flow along that surface.” The Coanda

Effect is extremely strong: even along the curved surface of the Coanda Block, the attractive force

between the wall and injected particle stream continues for quite some distance.

Utilizing the Coanda Effect

A completely different operating principle from that of typical centrifugal classifiers- the

Elbow-Jet will bring new levels of classification precision and efficiency to your operation.

Classification Principle

An ejector unit accelerates particles before being injected by compressed air through a feed nozzle into the classifier. Then, by the Coanda Effect*, the Jetstream will tend to flow along the coanda block. Each particle injected into the classifier has an inertia dependent on its size (mass). The smaller particles, with little inertia, will be highly susceptible to the Coanda Effect and will flow along closer to the Coanda Block.The larger particles, with more inertia, will be less affected by the Coanda Effect and will fly farther out into the carrier air jet. Here, by setting moveable classifications edges as appropriate, particle can be classified by size with astonishing accuracy and efficiency.